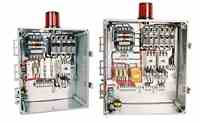

Duplex Pump Station Control Panels

- SPI Model SDC12B Duplex Control Panel

120/230 VAC, 0-20 FLA, Control Circuit Breaker

Item #:50A506

Our Price: $1025.00MSRP: $1250.00 - Alderon Check It Duplex Control Panel

120/230 VAC, 0-20 FLA

Item #:2010641

Product VideoOur Price: $1199.00MSRP: $1589.00 - Alderon Go2 Duplex Control Panel

120/230 VAC, 0-20 FLA, Power Relay

Item #:2010538

Product VideoOur Price: $879.00MSRP: $1210.00 - Alderon Flex Power Pak Duplex Time or Demand Dose Control Panel

120/230 VAC, 0-15 FLA, Clear Door, Power Relay

Item #:2010697

Product VideoOur Price: $1099.00MSRP: $1399.00 - Alderon Flex Panel Duplex Time or Demand Dose Control Panel

120/230 VAC, 0-15 FLA, Solid Door, Motor Contactor, Alarm Beacon

Item #:2010863

Product VideoOur Price: $1449.00MSRP: $2075.00 - SPI Model SDC12B Duplex Control Panel with Elapsed Time Meters

120/230 VAC, 0-20 FLA, ETM for Pumps

Item #:50A506-C1-C4

Our Price: $1225.00MSRP: $1499.00 - SPI Model SDC3B240 Three Phase Duplex Control Panel

240 VAC, 3 Phase

Item #:50A509

Our Price: $2195.00MSRP: $2950.00 - SPI Model SDC3B460 Three Phase Duplex Control Panel

460 VAC, 3 Phase

Item #:50A510

Our Price: $3225.00MSRP: $3995.00 - SPI Duplex Time Dosing Control Panel

120/230 VAC, 0-20 FLA, Analog Timer

Item #:50A810

Our Price: $1660.00MSRP: $1999.00

DUPLEX SEWAGE AND EFFLUENT PUMP CONTROLS

Our duplex control panels are designed to manage and monitor pump stations with two submersible pumps, making them perfect for lift stations and septic systems. Built for durability and efficiency, they offer:

- Automatic Pump Alternation: Built-in relay alternates pumps to balance wear and extend system life.

- High Water Alarm: Immediate alerts for pump failures or high water levels to prevent system issues.

- Circuit Protection: Equipped with circuit breakers and fuses to safeguard pumps and alarm circuits.

- Float Switch Compatibility: Supports 3 or 4 mechanical float switches (PUMP OFF, PUMP ON, HIGH LEVEL, and optional PUMP 2 ON for 4-float setups) for precise control.

- Time Dosing Capabilities: Distributes wastewater flow evenly throughout the day, ideal for systems with high peak usage.

Duplex panels are the go-to choice for systems requiring a backup pump. If one pump fails, the second kicks in automatically, and the high water alarm notifies you instantly, ensuring uninterrupted operation.

DUPLEX CONTROL PANEL APPLICATIONS

Duplex control panels are designed with redundancy in mind, making them the preferred solution for critical applications where downtime is not an option. If one pump fails, the second pump automatically takes over, and the high water alarm notifies you of the issue, minimizing the risk of system overflow or damage. This backup functionality is especially valuable for:

- Residential Sewage Lift Stations: Ensures continuous operation for homes with high wastewater output.

- Commercial Lift Stations: Manages heavy-duty wastewater transfer in community or municipal systems.

- Commercial Properties: Supports businesses like restaurants or hotels with high-volume effluent disposal requirements.

The most common application for a duplex control panel is a system that needs a backup pump in place in case the original pump fails. Our Duplex panels will alternate cycles between the two pumps, making sure both are in working order throughout the lives of the pumps. If one of the pumps fails, the panel will give the high water alarm, and automatically kick on the other pump. This type of set up ensures that you will always have at least one pump in working order.

OPERATION OF A DUPLEX CONTROL PANEL

A standard duplex control panel can operate with 3 or 4 float switches. The standard 3 float setup has PUMP OFF, PUMP ON, and HIGH LEVEL floats. A 4 float setup would have a PUMP OFF, PUMP 1 ON (LEAD ON), PUMP 2 ON (LAG ON), and HIGH LEVEL floats.

The control panel has an alternating relay that switches between PUMP 1 and PUMP 2 after every cycle during automatic operation. This means that once the liquid level reaches the PUMP ON float that PUMP 1 will run until the liquid level reaches the PUMP OFF float. At this time the alternating relay will switch to PUMP 2 and it will follow this same cycle and the alternating relay will switch back to PUMP 1 and so on.

If you are using a 4 float setup, and the water level reaches the PUMP 2 ON (LAG ON) float switch, then the alternate pump not set to normally come on will be activated. The only reason the water level should ever reach the PUMP 2 ON (LAG ON) switch is because PUMP 1 has failed or cannot keep up with the incoming flow.

If the liquid level reaches the HIGH LEVEL float, the alarm light and buzzer on the control panel will be activated.

WHY SHOP WITH SEPTIC SOLUTIONS?

- Unmatched Selection: We carry the largest inventory of duplex control panels, ensuring you find the perfect match for your system.

- Fast, Free Shipping: Most in-stock items ship the same day at no additional cost, getting your project back on track quickly.

- Expert Support: Our knowledgeable team is here to assist with product selection, installation guidance, and troubleshooting.

- Trusted Quality: We partner with leading manufacturers to deliver durable, high-performance panels that meet industry standards.

- Competitive Pricing: Get premium products at affordable prices, with no compromise on quality or features.

Don’t leave your septic system to chance. Equip it with a reliable duplex control panel from Septic Solutions and enjoy worry-free operation, even in demanding conditions. Whether you’re upgrading an existing system or installing a new one, our panels provide the control, protection, and redundancy you need to avoid costly downtime.

Shop our duplex control panels today and experience the Septic Solutions difference. Have questions? Reach out to our team at (877)-925-5132 or sales@septicsolutions.com for expert advice or browse our full range of septic system components to complete your project.